DIY Bathroom Remodel Step-by-Step

DIY Bathroom Remodel Step-by-Step: How We Completely Transformed Our Space

We’ve wanted to change the bathroom design ever since we moved into our home. Luckily, the building we live in was planning to replace all the water pipes, so we decided this was the perfect opportunity to take on our most ambitious project yet: a full bathroom remodel. In this step-by-step guide, we’ll share how we tackled each part of the renovation, from tearing down walls to finishing with a stunning modern look. If you’ve ever wondered how to approach a DIY bathroom remodel step-by-step, this guide is for you!

Before and after picture

Before We Started: A Fresh Start for the Bathroom

Our bathroom was cramped and outdated. The old tiles, low ceiling, and unused pipes cluttered the space and made it feel smaller than it actually was. We decided to give it a full makeover to create a more spacious, modern, and functional room. Here’s how we did it!

Step 1: Take Down the Ceiling and Sink Cabinet

We started our DIY bathroom remodel step-by-step by clearing out the existing ceiling and removing the sink cabinet. Since we planned to raise the ceiling and replace the sink, we needed to create an open, blank canvas for the new design.

How We Did It:

- First, we unscrewed and disconnected the sink from the plumbing, carefully removing it from the wall.

- Next, we took down the ceiling using a crowbar to pry the panels away. It was a messy job, but once the ceiling came down, we already noticed the room feeling more open.

- We also removed any old fixtures, lights, and vents that were attached to the ceiling.

Pro Tip: Before removing fixtures, make sure to turn off the water supply and electricity to the bathroom to avoid accidents.

Tools Used: Crowbar, Screwdriver, Wrench

Materials Removed: Ceiling Panels, Sink Cabinet

Step 2: Cut Down Half of the Wall Over the Toilet to Open Up the Space

The bathroom had a half wall above the toilet that made the space feel cramped. To create a more open and spacious feel, we decided to cut down this wall.

How We Did It:

- We used a saw to carefully cut through the drywall of the half wall, exposing the underlying framework.

- Once the wall was open, we removed the supporting studs, taking care not to damage the surrounding structure.

- After the wall was removed, we patched up any exposed edges to create a smooth finish.

Pro Tip: Always check for hidden pipes or electrical wires inside the wall before cutting. Use a stud finder and consult building plans if necessary.

Tools Used: Saw, Crowbar, Stud Finder

Materials Removed: Drywall, Wooden Studs

Step 3: Remove Old, Unused Pipes to Create More Space

Next, we tackled one of the most challenging parts of this DIY bathroom remodel step-by-step: removing old, unused pipes in the corner behind the wall. This was a tricky task due to the thickness and position of the pipes.

How We Did It:

- We carefully opened the drywall in the corner to expose the pipes. Using a pipe cutter, we cut away the sections of pipe that were no longer in use.

- We then patched up the drywall, filling in the gaps left by the pipes to create more usable space in the bathroom.

Pro Tip: If you’re unsure about removing pipes, consult a professional plumber. Working with plumbing requires caution to avoid damaging essential water lines.

Tools Used: Pipe Cutter, Crowbar, Drywall Patching Kit

Materials Removed: Old Pipes, Drywall

Step 4: Rebuild the Wall in the Shower Area

When the pipe-chasing company replaced the water pipes, they had to open up the wall in the shower. To restore this wall, we needed to build a new structure that was waterproof and durable.

How We Did It:

- We first built a wooden frame to outline the shape of the new wall.

- Next, we covered the frame with moisture-resistant drywall to prevent any water damage.

- For additional protection, we applied a layer of 100% waterproof membrane over the drywall, ensuring that the wall could withstand the moisture of a shower area.

Pro Tip: Use damp-resistant drywall in bathrooms to prevent mold and water damage. Applying a waterproof membrane adds an extra layer of protection.

Tools Used: Saw, Screwdriver, Waterproof Membrane

Materials Used: Wooden Beams, Damp-Free Drywall

Step 5: Even Out the Walls with Cement

Removing the old tiles would have been a time-consuming and messy process, so instead, we opted to even out the walls using cement to create a smooth surface for the new design.

How We Did It:

- We applied a layer of cement over the existing tiles, smoothing it out with a trowel.

- We continued this process around the entire bathroom to ensure all the walls were level and ready for the next steps.

Pro Tip: Applying cement directly onto old tiles is a great way to save time and create an even surface for new finishes.

Tools Used: Trowel, Mixing Bucket

Materials Used: Cement

Step 6: Build the New Sink Cabinet

Instead of buying an expensive sink cabinet, we built a custom one using a small IKEA drawer system and MDF plates. This allowed us to customize the size and look of the cabinet.

How We Did It:

- We started by assembling the IKEA drawer system and then cut MDF plates to create a tabletop and additional cabinet space.

- We attached the MDF plates to the IKEA drawers, securing them with screws to create a sturdy frame.

Pro Tip: MDF is easy to work with and can be cut to any shape, making it perfect for custom projects like this.

Tools Used: Saw, Screwdriver, Drill

Materials Used: IKEA Drawer System, MDF Plates

Step 7: Create a Rounded Corner with Bendable MDF

Annie wanted a rounded corner for the cabinet, so we used bendable MDF to achieve this unique design element.

How We Did It:

- We cut a piece of bendable MDF to the desired size and shape.

- Using screws and wood glue, we carefully attached it to the cabinet, shaping it into a smooth, rounded corner.

Pro Tip: Bendable MDF is perfect for creating curves and unique shapes in furniture projects. Be patient while securing it to maintain the curve.

Tools Used: Saw, Screwdriver, Clamps

Materials Used: Bendable MDF, Wood Glue

Step 8: Apply Micro Cement to Walls and Cabinet

Now it was time to give the bathroom its new look by applying micro cement to the walls and cabinet. Micro cement is a versatile and waterproof material that can be applied to different surfaces, making it ideal for bathroom use.

How We Did It:

- In the shower area, we first applied a layer of 100% waterproof membrane over the new drywall, then applied the micro cement on top.

- We used a trowel to spread the micro cement evenly across all the walls, including the surface of the sink cabinet.

Pro Tip: Apply micro cement in thin layers to avoid cracks and ensure a smooth finish. Use a waterproof sealer afterward to protect the surface.

Tools Used: Trowel, Waterproof Membrane, Paint Roller

Materials Used: Micro Cement, Waterproof Sealer

Step 9: Raise the Ceiling

One of the most transformative changes was raising the ceiling in the toilet area by 40 centimeters. This made the room feel more spacious and open.

How We Did It:

- We built a wooden frame on the ceiling to create a new support structure.

- Next, we attached damp-free drywall to the frame, providing a smooth surface for painting later on.

Pro Tip: Ensure proper ventilation in the ceiling to avoid moisture buildup.

Tools Used: Saw, Screwdriver, Drill

Materials Used: Wooden Beams, Damp-Free Drywall

Step 10: Add Ventilation and Hatch for Water Pipes

Proper ventilation is essential in any bathroom. We added a vent to the ceiling to keep moisture levels in check. Additionally, we included a hatch for easy access to the water pipes, allowing for future maintenance.

How We Did It:

- We cut a hole in the ceiling drywall for the vent and hatch, then secured them in place using screws.

Pro Tip: Adding a hatch provides convenient access to utilities while keeping them hidden from view.

Tools Used: Saw, Screwdriver

Materials Used: Vent, Access Hatch

Step 11: Spackle the Ceiling

To give the ceiling a smooth, finished look, we applied a layer of spackle over the seams and screws.

How We Did It:

- Using a putty knife, we spread the spackle evenly over the joints and screw holes.

- After it dried, we sanded it down for a flawless finish.

Tools Used: Putty Knife, Sandpaper

Materials Used: Spackle

Step 12: Install the Sink, Faucet, and Shower

With the structure in place, it was time to install the new sink, faucet, and shower. We carefully followed the manufacturer’s instructions to ensure proper installation.

How We Did It:

- We connected the plumbing fixtures to the water lines, securing them in place with wrenches and plumber’s tape.

Tools Used: Wrench, Plumber’s Tape

Materials Used: Sink, Faucet, Shower Fixtures

Step 13: Paint the Ceiling

We painted the ceiling with a moisture-resistant paint to match the rest of the bathroom’s sleek, modern look.

Pro Tip: Use moisture-resistant paint in bathrooms to prevent mold and mildew.

Tools Used: Paint Roller, Brush

Materials Used: Moisture-Resistant Paint

Step 14: Add Gray Floor Tiles

To give the bathroom a polished finish, we installed large gray tiles on the floor.

How We Did It:

- We primed the old floor and cut the tiles to fit the space.

- We applied tile adhesive and laid the tiles down, making sure to slope the area around the shower for drainage.

Pro Tip: Use spacers to ensure even gaps between tiles and achieve a professional look.

Tools Used: Tile Cutter, Trowel

Materials Used: Floor Tiles, Tile Adhesive, Primer

Step 15: Install a Small Glass Wall in the Shower

To prevent water from splashing out of the shower, we installed a small glass wall.

How We Did It:

- We drilled holes for the brackets, then secured the glass panel in place.

Tools Used: Drill, Screwdriver

Materials Used: Glass Panel, Brackets

Step 16: Apply Sealer to the Micro Cement

Finally, we added a sealer to the micro cement to protect the surface and ensure it remains waterproof.

How We Did It:

- We used a paint roller to apply the sealer evenly across the walls and sink cabinet.

Tools Used: Paint Roller

Materials Used: Waterproof Sealer

Final Result: Our Dream Bathroom Remodel Complete!

And that’s it! Our DIY bathroom remodel step-by-step transformed our outdated space into a modern, sleek, and functional bathroom. From raising the ceiling to installing custom cabinetry, this project was a labor of love, and we couldn’t be happier with the result.

Dog House Build in 6 easy steps

Dog House Build in 6 Easy Steps

Looking for a unique dog house build that not only gives your furry friend a cozy space but also matches the style of your home? We’ve got you covered! Our goal was to use up some dead space under the stairs and create a dog house that blended seamlessly with our New York Loft Style room. Here’s how we turned this idea into reality in just six simple steps!

The Overall Idea for the Dog House Build

We had some unused space under the stairs that connected our couch area to the dining room, and we thought this would be the perfect spot for a dog house. Since our room already featured a New York Loft Style vibe with industrial glass walls, we wanted the dog house to match this aesthetic. By reusing some materials and putting in a bit of DIY effort, we managed to create a stylish dog house that perfectly fits the room’s design.

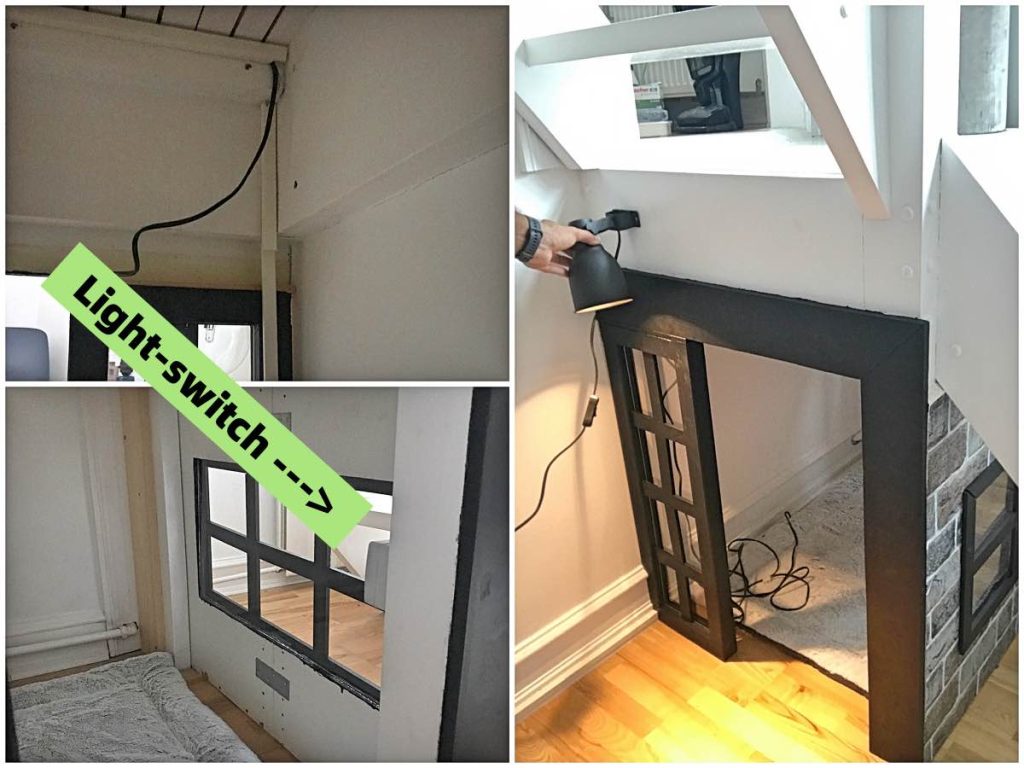

Step 1: Build the front window

Since we are huge fans of New York-style glass walls and already had them in the room, we decided to incorporate a similar design into the dog house build. The first step was to create a front window that mimics this industrial style.

To start, we built a simple wooden frame to house the window. We measured the opening where the window would go, then cut the wood to size and assembled the frame using screws. This not only gave the dog house a stylish look but also allowed us to add a unique design element to the front of the house.

Pro Tip: Make sure to sand down any rough edges on the wooden frame to ensure a smooth finish when it’s painted.

Tools: Saw, Screwdriver, Sandpaper

Materials: Wooden Boards, Screws

Step 2: Paint and cut the window

Next, we painted the wooden frame black to match the industrial look of the room. We used blackboard paint because it has a nice matte finish, which adds to the modern vibe of the dog house build.

After painting, we cut out a piece of 3mm plexiglass to fit inside the frame. We found the plexiglass at a local store, and the multi-cutter tool made it easy to cut it to the right size. If you don’t already own a multi-cutter, this is a great investment for all kinds of DIY projects (Check out our article on the 11 Most Essential Handyman Tools for more on this must-have tool).

Pro Tip: Use painter’s tape on the plexiglass while cutting to prevent scratches and ensure a clean edge.

Tools: Multi-Cutter Tool, Paintbrush

Materials: Plexiglass, Blackboard Paint

Step 3: Time to create a “brick wall” with a window inside

This part of the dog house build was both fun and challenging! We aimed to create a faux brick wall with a New York-style window inside. Here’s how we did it:

First, we cut out a plywood sheet to serve as the wall. Using the wooden frame we built in Step 1, we cut an opening in the plywood for the window. To give the wall that classic brick appearance, we applied a sheet of brick-patterned wallpaper over the plywood.

Once the wallpaper was in place, we installed the plexiglass window, securing it with the black-painted wooden frame. This little touch added an industrial flair to the dog house, perfectly tying it into the rest of the room’s decor.

Pro Tip: Apply the brick-patterned wallpaper carefully, using a squeegee to smooth out any air bubbles for a seamless finish.

Tools: Utility Knife, Ruler, Squeegee

Materials: Plywood Sheet, Brick-Pattern Wallpaper, Glue

Then we applied some brick-wall wallpaper, and finally we added plexiglass and a black-painted wooden frame.

Step 4: Add a door-frame

Now it was time to add a stylish entrance for our pup! We built a door frame around the opening of the dog house using small wooden boards. We then painted it black with the same blackboard paint to match the window frame.

The matte finish of the blackboard paint gives the dog house a chic, modern look, while also providing a durable surface that can handle a bit of wear and tear.

Pro Tip: Use painter’s tape along the edges of the frame to ensure clean, sharp lines when painting.

Tools: Saw, Paintbrush

Materials: Wooden Boards, Blackboard Paint

Step 5: Add a light for the dog

Nicolai came up with the brilliant idea of adding a light inside the dog house, making it feel even cozier. We installed a light fixture with a large switch inside the dog house, so it could be easily turned on and off.

For the dog’s safety, we made sure to hide all the wiring securely inside the walls where it would be out of reach. The final touch was adding a protective cover over the switch to keep it safe from any curious paws.

Pro Tip: Always use low-voltage lighting and make sure all wires are well-concealed to prevent any chewing accidents.

Tools: Drill, Screwdriver

Materials: Light Fixture, Wiring, Switch

Step 6: Make a cozy and wholaa!

With the structural elements complete, the final step in our dog house build was to make it cozy and inviting. We added a soft dog bed inside, along with a couple of cozy blankets. The combination of the faux brick wall, glass window, and soft interior created the perfect space for our new furry family member.

And there you have it—our custom dog house build was done! The final product not only provided a cozy hideaway for our pup but also matched the New York loft style of our home, adding a stylish touch to an otherwise unused space.

Final Thoughts on Our Dog House Build

Creating a dog house build that fits both your pet’s needs and your home’s style is easier than you might think. With some creativity and the right materials, you can turn unused spaces into functional, eye-catching features. This project cost us about $200 and took 15 hours to complete, but the result was worth every minute and penny.

So, if you’re ready to build a unique and stylish dog house, follow these steps to create a space your dog will love and that seamlessly fits into your home’s design!

DIY Hallway makeover

DIY Hallway Makeover

Are you ready to see how we completed a stunning DIY hallway makeover for less than $300? Hallways are often overlooked, yet they’re the first impression guests get when they step into your home. With some creativity, the right tools, and a bit of elbow grease, you can completely transform your hallway into a functional and stylish space.

Follow along to see how we gave our hallway a fresh, new look!

The Hallway Before: A Blank Canvas

When we first moved in, the hallway felt cramped and dark. The previous owners had left a large closet in the middle of the space to provide storage and conceal the electricity control board. However, the bulky closet made the hallway feel much smaller than it actually was. That’s when we decided it was time for a DIY hallway makeover to open up the space and create a more welcoming entryway.

Step 1: Choose color

The first step in our DIY hallway makeover was selecting the perfect paint color. We knew we wanted to paint the entire hallway to refresh the look, but finding the right shade was trickier than expected. After testing four different samples, we finally settled on a beautiful green-grey olive color from our go-to store, Bauhaus. The warm, earthy tones of this color would bring a modern yet cozy vibe to the hallway.

Pro Tip: Take your time when choosing a paint color. Test different shades directly on the walls to see how they look in various lighting throughout the day.

Tools: Paintbrush, Roller

Materials: Paint Samples, Tape

Step 2: Remove old furniture

With the color chosen, the next step in our DIY hallway makeover was to remove the old closet. It took some wrestling, but we eventually freed the bulky piece from its spot in the middle of the hallway. Instantly, the space felt more open and inviting! Removing the closet also revealed some damaged areas on the walls, which we filled and covered with a basic coat of white paint.

Pro Tip: Make sure you have the right tools on hand for this phase. If you’re not sure where to start, check out our list of the 11 Most Essential Handyman Tools to build your tool collection.

Tools: Hammer, Crowbar, Putty Knife

Materials: Filler, Sandpaper, Primer

Step 3: Paint

Once the hallway was cleared, it was time to paint! We applied two layers of our chosen olive-green paint, and the transformation was immediate. The new color gave the hallway a fresh, modern feel and completely changed the room’s character. This step was crucial in setting the tone for the rest of the DIY hallway makeover.

Pro Tip: Always start with a coat of primer if your walls are a darker shade or have stains. This will help the new color go on more smoothly and evenly.

Tools: Paintbrush, Roller, Paint Tray

Materials: Wall Paint, Primer

Step 4: Build furniture

After removing the old closet, we needed new storage solutions that wouldn’t overwhelm the space. We spent hours researching and finally found two pieces of furniture from IKEA that were perfect for our DIY hallway makeover—a shoe drawer for everyday items and a combined bench/drawer. We bought them second-hand at a bargain price, keeping our budget in check.

The bench provided a functional spot for putting on and taking off shoes, while the large drawer underneath offered a place to store work bags that used to clutter the hallway. To cover up the electricity control board, we built a simple frame using leftover wood.

Pro Tip: Opt for second-hand furniture to keep costs low, and don’t be afraid to make minor modifications to fit your space.

Tools: Screwdriver, Saw, Measuring Tape

Materials: IKEA Furniture, Wood for Frame

Step 5: Adjust furniture to hallway!

To make the new furniture fit seamlessly into our hallway, we had to make some adjustments. We trimmed the bench/drawer and the shoe drawer to align perfectly with the hallway’s dimensions. A few small cuts in the furniture and adjustments to the floor molding did the trick, creating a more custom-built appearance.

Pro Tip: Always measure twice before cutting! A precise fit makes all the difference in achieving a polished look in your DIY hallway makeover.

Tools: Saw, Sandpaper

Materials: Wood Glue, Screws

Step 6: Front of drawer

Annie came up with a brilliant idea to add some personality to the large drawer under the bench. She purchased 400 wooden ice sticks and arranged them in a herringbone pattern on the drawer front. To tie the look together, she painted sections of the sticks in the same green color as the hallway walls. This little DIY touch not only matched the room’s color scheme but also created a stunning focal point that looks far more expensive than it actually was!

Pro Tip: Adding small DIY elements like this can elevate the design and make your space feel unique. It might take some extra time, but the results are worth it!

Tools: Hot Glue Gun, Paintbrush

Materials: Wooden Ice Sticks, Leftover Paint

It did take quite some time, but the final result was all worth it!

Final Result: A Stunning DIY Hallway Makeover

The last step in our DIY hallway makeover was to paint the rest of the bench in the same green color and install hooks for jackets and small bags. These simple additions completed the space, creating a functional and inviting entryway that feels organized and stylish.

And here is the final result! Our hallway now has a fresh, modern vibe that fits the aesthetic of the rest of our home. By carefully planning each step and adding personalized touches, we achieved a complete transformation for just $280.

Final Thoughts: DIY Hallway Makeover on a Budget

A DIY hallway makeover doesn’t have to be expensive or complicated. With a bit of planning, creativity, and some DIY magic, you can turn a cramped, cluttered hallway into a welcoming and stylish space. The key is to focus on what will make the biggest impact—whether it’s choosing the right paint color, selecting functional furniture, or adding unique DIY elements like our herringbone drawer front.

So, ready to tackle your own hallway makeover? Use these steps as your guide, and create an entryway that makes you smile every time you walk through the door!

New York Loft Style Home Office

New York Loft Style Home Office

A New York loft style home office in the heart of Copenhagen? Not the most common find, but that didn’t stop us from bringing this dream to life! With some creativity, a bit of elbow grease, and plenty of inspiration, we transformed our loft area into a workspace with that iconic New York loft vibe. If you’re looking to create your own industrial-inspired office, follow along for all the details of how we did it!

The Area Before: A Blank Canvas

When we moved into the apartment, the loft area was essentially a blank canvas. The room has a ceiling height of over 4 meters, and the previous owners had built a loft to maximize the vertical space. Although the loft structure was useful, it lacked the character we were aiming for. Measuring around 2.2 meters from the wall to the handrail and 3.4 meters along its length, the area had plenty of potential for our New York loft style home office makeover.

The flooring was basic wood, which could have been great, but the type and color didn’t match the industrial loft vibe we were aiming for. We decided to start with the floor and work our way up to transform this space.

Step 1: Sandpaper the floor and add paint

The first step in creating our New York loft style home office was revamping the floor. Using a circular grinder, we sanded down the top layer of the wooden floor to smooth out imperfections and prepare it for a fresh coat of paint. Once the floor was ready, we applied three layers of white floor paint to achieve a clean, modern base that would complement the industrial elements we planned to add later.

Pro Tip: Using multiple coats of paint ensures a durable, long-lasting finish that can withstand the wear and tear of a busy home office.

Tools: Circular Grinder, Paintbrush, Paint Roller

Materials: Sandpaper, White Floor Paint

Step 2 - Build office table

With the floor looking fresh and modern, the next step was to build a statement office table. We had an older plank of wood stored from a previous home, and its rich color and grain pattern fit perfectly with the New York loft style home office theme we envisioned.

To give the table a unique, edgy look, we decided to extend the tabletop down to the floor, using it as a leg. We cut the plank with a circular saw at a 45-degree angle to create a seamless joint where the tabletop meets the floor. Small iron angles were used underneath for additional support.

To mount the table on the wall, we attached a square piece of wood to the wall, creating a sturdy base for the table to rest on. We then screwed the table into the wall-mounted support from underneath, achieving a clean, minimalist appearance.

Pro Tip: Using iron angles provides invisible support, maintaining the industrial aesthetic while ensuring the table remains stable and durable.

Tools: Circular Saw, Screwdriver, Level

Materials: Iron Angles, Screws, Wall-Mounted Support

Step 3: Tame the Chaos with Storage Solutions

While we loved the initial table design, the space was quickly turning into a chaotic mess with office supplies scattered everywhere. To maintain the sleek, organized look of our New York loft style home office, we added a small drawer unit to store essentials like paper, pens, and cables. This simple addition made a big difference in keeping the space tidy and functional.

Pro Tip: Incorporate storage solutions that complement your design. For an industrial loft look, consider metal or dark wood drawers with minimalist lines.

Tools: Screwdriver (for assembly)

Materials: Drawer Unit

Step 4: Add New York Loft Style to the home office

A true New York loft style home office isn’t complete without an exposed brick wall. We decided to strip away the outer layer of the wall to reveal the raw brick underneath. This step required some serious effort, but the results were well worth it!

We used a hammer drill with a flat head to remove the plaster and expose the beautiful brick. This method was much faster and more efficient than doing it manually. Once the brick was fully exposed, the room started to embody that classic loft aesthetic, instantly adding warmth and character to the space.

Pro Tip: If you want a cleaner, less dusty approach, consider using faux brick panels for a similar effect with less mess.

Tools: Hammer Drill, Flat Head Chisel

Materials: Dust Mask, Protective Sheets

Well now we were getting closer to get the right vibe!

Step 5: Build a New York glass wall

The next step was the most dramatic: replacing the existing handrail with an industrial glass wall. This addition was key to achieving the New York loft style home office look we were going for. We removed the old handrail and installed a DIY industrial glass wall, which you can read about in detail in our article: DIY Industrial Glass Wall.

The glass wall not only added an authentic industrial feel but also allowed light to flow freely between the loft and the rest of the room, making the space feel more open and airy.

Pro Tip: Industrial glass walls can be pricey, but using glass shower walls as a budget-friendly alternative gives you the same aesthetic at a fraction of the cost.

Tools: Multi-Cutter Tool, Measuring Tape, Drill

Materials: Glass Shower Panels, Support Frame, Screws

Step 6: Add some nice furniture and there we go!

Finally, it was time to add those finishing touches that would bring our New York loft style home office vision to life. We went shopping and found a few key pieces: a sleek, modern chair, a stylish carpet, and a lovely drawer unit that fit perfectly under the table. These elements added the comfort and functionality needed for a productive workspace.

The final step was adding a few industrial-style decor pieces to complete the look, such as metal lamps, exposed bulbs, and minimalistic office accessories. With these last touches, our dream of a New York loft-style office became a reality!

Pro Tip: Choose furniture and decor that emphasize clean lines and neutral colors with a touch of rustic or industrial elements, like metal frames or reclaimed wood, to maintain the loft aesthetic.

Tools: None (for final decor)

Materials: Chair, Carpet, Drawer Unit, Decor Items

Final Result: A New York Loft Style Home Office in Copenhagen

And there you have it! Our New York loft style home office turned out exactly as we had envisioned—a functional, stylish workspace that feels straight out of a Manhattan loft. The total cost came in at around $1,000, which is a small price to pay for such a dramatic transformation.

By following these steps, you too can create your own New York loft-inspired office, even if you’re miles away from the Big Apple. With the right design elements, a bit of DIY effort, and some creative thinking, you’ll be well on your way to achieving this iconic style in your own home.

Ready to start your New York loft-style makeover? Grab your tools and get building!

DIY Industrial Glass Wall

DIY Industrial Glass Wall

Have you ever dreamed of creating a stunning DIY industrial glass wall but were put off by the high cost and complicated process? What if I told you there’s an easy and affordable way to achieve that chic, New York loft-style look? In this guide, we’ll show you how to build your own industrial glass wall for just $450! Read on, and get ready to be amazed by how simple and budget-friendly this project can be.

Step 1: Order glass shower walls

The first step in building your DIY industrial glass wall is finding the right materials at an affordable price. We spent some time searching online for New York-style glass walls, but most of them were priced well over $1000 each—way out of our budget! Then, we stumbled upon a game-changer: glass shower walls.

We found beautiful glass shower walls for only $212 each. These shower doors have the industrial look we were after, with metal framing that mimics the style of traditional industrial glass walls. We ordered two of these to build our glass wall, keeping the total cost low without sacrificing style.

Pro Tip: Search for “New York Glass Shower Walls” to find budget-friendly options that suit your project.

Materials: 2 Glass Shower Walls

Cost: $424 (for two walls)

Step 2: Clear area

Now that you have your materials, it’s time to clear the area where your DIY industrial glass wall will go. We started by removing the handrail in the loft area using a handsaw. Make sure to clear out any unnecessary items and prepare the space for the installation.

While working on the glass wall, we also took the opportunity to repair a nearby brick wall. If you’re interested in adding more industrial elements to your space, check out our guide on building a DIY Brick Wall.

Tools: Handsaw, Screwdriver

Materials: Drop Cloths, Tarp for Dust Protection

Step 3: Prepare the Installation Area

After clearing the space, it’s time to prepare for the installation of your DIY industrial glass wall. In our case, the loft area where the wall would be installed was only 178 cm high, while the glass walls were 220 cm high and 90 cm wide. To make them fit, we had to cut away 2 cm from the floor.

Using a multi-cutter tool, we carefully cut the edge of the floor to create the space needed for the glass wall. This step requires precision, so take your time to measure and cut accurately.

Pro Tip: If you don’t already own a multi-cutter tool, consider investing in one. It’s a versatile tool that can handle a range of tasks, making it invaluable for this project.

Tools: Multi-Cutter Tool, Measuring Tape

Materials: Drop Cloths, Mask, Safety Glasses

I used my Multi Cutter tool for this job, cutting from both sides of the edge of the floor. Check out the 11 Most Essential Handyman Tools to read more about the Multi Cutter Tool, it is AMAZING!

Step 4: Prepare the Ceiling

The next part of the preparation process involved modifying the ceiling. We had a nice rounded corner with a pattern that needed to be trimmed to fit the glass wall snugly. Once again, the multi-cutter tool came to the rescue, allowing us to make the necessary adjustments quickly and cleanly.

Pro Tip: Use painter’s tape to outline the area you need to cut on the ceiling to ensure a straight and precise cut.

Tools: Multi-Cutter Tool, Painter’s Tape

Materials: Dust Mask, Safety Glasses

Step 5: Test if the walls fit the space

With the floor and ceiling modifications complete, it’s time to test the fit of the glass walls. Carefully position the walls in place to ensure they fit properly within the space. We put up two temporary poles on the outside to test how the glass walls would align and function.

Pro Tip: Testing the fit before permanently installing the walls helps you identify and address any issues early, saving time and hassle later on.

Tools: Measuring Tape, Temporary Support Poles

Materials: Drop Cloths

Step 6: Building a frame to hold the walls

Since we planned to stack the two glass shower doors on top of each other, we needed a sturdy frame to support them. Luckily, the shower doors came with attachment rails. We cut these rails into several pieces and drilled holes through them to attach them to the ceiling and brick wall securely.

Precision is key when building the frame. Use a digital level and ruler to ensure that everything is perfectly aligned. This step will determine the stability and final look of your DIY industrial glass wall.

Pro Tip: Double-check all measurements before cutting the rails and drilling holes. A small mistake at this stage can affect the overall fit and stability of your glass wall.

Tools: Saw, Drill, Digital Level, Ruler

Materials: Attachment Rails, Screws

Step 7: Installing the walls

Here comes the moment of truth—installing the glass walls! We carefully stacked the two shower doors on top of each other and sealed them within the frame we built. To secure the structure, we connected a solid pole between the ceiling and the floor. This pole acts as a support, holding the glass walls firmly in place.

Pro Tip: Get a helping hand for this step, as handling large glass panels can be tricky. Safety comes first, so use gloves and take your time during installation.

Tools: Drill, Level, Screwdriver

Materials: Solid Pole, Screws, Sealing Tape (optional)

Step 8: Add Finishing Details

With the glass walls securely in place, it’s time to add the finishing touches to your DIY industrial glass wall. We used some leftover wooden sticks to create a simple handrail and added filler to cover any small gaps or cracks in the installation. After smoothing everything with sandpaper, the wall was almost complete!

Pro Tip: Using a high-quality filler ensures a smooth finish, making the entire structure look polished and professional.

Tools: Filler, Sandpaper, Putty Knife

Materials: Wooden Sticks, Filler

Step 9: Paint

For the final step, we painted the wood around the glass wall using blackboard paint. This particular paint has a beautiful matte black finish that perfectly complements the industrial style. A couple of coats were all it took to achieve a sleek, modern look.

Pro Tip: Use a small paintbrush to reach tight corners and ensure an even coat for a flawless finish.

Tools: Paintbrush, Drop Cloths

Materials: Blackboard Paint, Painter’s Tape

Final result

And there you have it! A stunning DIY industrial glass wall that adds character and a touch of modern industrial design to any space. The total cost of $450 is a fraction of what you’d pay for a pre-made industrial glass wall, and the sense of accomplishment from building it yourself is priceless!

Final Thoughts on DIY Industrial Glass Wall

Building a DIY industrial glass wall is an exciting project that can dramatically transform your living space. By using glass shower walls and a bit of creativity, you can achieve a high-end, loft-style look without breaking the bank. The key to success lies in careful planning, precise measurements, and taking your time with the installation.

So, are you ready to add an industrial edge to your home? Follow these steps, and you’ll have a stunning glass wall that’s sure to impress!

DIY Brick Wall

DIY Brick Wall - 6 easy steps

Have you always dreamed of creating a DIY brick wall but never knew where to begin? The charm of exposed brick can transform a room, adding texture and a rustic, industrial vibe to your space. Fortunately, building your own brick wall is easier than you might think! Just follow these 6 simple steps, and you’ll become a DIY brick wall master in no time!

Step 1: Test your wall

Before diving into your DIY brick wall project, the first step is to confirm that you actually have a brick wall behind the outer layer. Start by covering the floor with protective material to catch any debris. Next, cut a small opening in the wallpaper (TAPET) to peek behind it. Using a hammer and a nail, carefully remove a small section of the outer layer of the wall.

If you find bricks underneath, congratulations! You’re ready to move on to the next step. If not, you might need to consider alternative ways to create the brick effect, like using faux brick panels. But if you’re lucky enough to have real brick behind the surface, this method will give you a genuine and stylish DIY brick wall.

Tools: Hammer, Nail, Utility Knife

Materials: Protective Floor Covering

Step 2: Check larger area

Once you’ve confirmed that there’s a brick wall hiding beneath the surface, it’s time to open up a larger area. Carefully remove more of the outer wall layer, taking your time to avoid damaging the bricks underneath.

After revealing a more extensive section of the wall, take a step back to assess the look and texture of the bricks. We found that our wall had a beautiful, rustic texture that was perfect for our DIY brick wall project, so we decided to go all in!

Pro Tip: Use a paint scraper or putty knife to help lift off stubborn patches of the outer wall layer without harming the bricks.

Tools: Hammer, Paint Scraper, Putty Knife

Materials: Drop Cloths

Step 3: Dust protection

The process of exposing a DIY brick wall creates a lot of dust, so it’s essential to protect yourself and your space. We quickly realized the importance of building a dust shield around the area, although our first attempt wasn’t entirely successful. Nevertheless, any barrier is better than none!

Use plastic sheets or tarp to cover furniture and other items in the room. Additionally, make sure to protect yourself with a mask and safety glasses to avoid inhaling dust and debris.

Pro Tip: Seal off the area with plastic sheeting and use painter’s tape to cover doorways to minimize the spread of dust to other parts of the house.

Tools: Plastic Sheets, Mask, Safety Glasses, Painter’s Tape

Materials: Tarp, Dust Mask

Do remember to protect yourself with mask and glasses.

Step 4: Use a hammer-drill and go crazy

Now, it’s time for the real fun to begin! With your protective gear on, use a hammer drill with a flat chisel head to break away the outer plaster or drywall layer. This tool speeds up the process and makes it much easier to reveal the beautiful bricks beneath. While the hammer drill isn’t usually on our list of essential handyman tools, it was an absolute lifesaver for this particular project!

Take care not to damage the bricks as you remove the outer layer. Work in small sections, and use gentle pressure to avoid chipping or cracking the brickwork. Patience is key here; go at a steady pace to achieve the best results.

Tools: Hammer Drill, Flat Chisel Head

Materials: Dust Mask, Safety Glasses

Step 5: Steel-brushing the DIY Brick Wall

After you’ve removed all of the outer wall material, it’s time to brush off the bricks to get rid of any loose debris and heavy dust particles. A steel brush works perfectly for this task, as it can scrape away stubborn bits of dust and dirt without damaging the brick surface.

Use firm, sweeping motions with the steel brush to clean off the bricks, revealing their natural color and texture. This step is crucial for achieving the classic, raw look of an exposed DIY brick wall.

Tools: Steel Brush

Materials: Protective Gloves

Step 6: Wash with water and done!

The final step to completing your DIY brick wall is to wash it down with water and a plastic brush. This step helps to remove any remaining dust and gives the bricks a clean, polished look. Gently scrub the wall with water, making sure not to saturate it too much.

Once you’ve washed the bricks and they’re dry, consider applying a sealing paint or clear coat. This optional step helps to keep the wall from shedding dust each time someone touches it. A sealing coat also enhances the brick’s color and texture, giving your DIY wall a professional finish.

Tools: Plastic Brush, Spray Bottle

Materials: Water, Clear Sealing Paint (Optional)

And There You Have It!

Your DIY brick wall is now complete! With just a few simple steps and a bit of patience, you’ve transformed a plain wall into a stunning, rustic feature that adds character and style to any room. The beauty of a brick wall is in its imperfections, so don’t stress over minor flaws – they add to the authentic, raw aesthetic that makes brick walls so popular.

Extra-stories from the loft area

Before we embarked on this DIY brick wall journey, we did a lot of redesigns in our loft area, including painting the floors, building an office table, and revamping the handrail to create a New York loft-inspired look. If you’re interested in other DIY projects that complement your brick wall, feel free to explore the following articles:

These projects show how a DIY brick wall can seamlessly fit into various design themes, enhancing the overall aesthetic of your home.

Final Thoughts on Creating a DIY Brick Wall

Building a DIY brick wall is a straightforward yet highly impactful way to change the look and feel of a room. With just a few tools, a bit of elbow grease, and some creativity, you can bring warmth and character to your space. The natural texture of exposed brick creates a focal point that suits both modern and vintage styles.

So, if you’ve ever hesitated to start your own brick wall project, now is the time to go for it! Follow these six simple steps, and you’ll be on your way to having a stunning DIY brick wall that everyone will admire.

Building a walk in closet in basement – step by step

Building a walk in closet in basement – step by step

Have you ever dreamed of building a walk-in closet in your basement but felt too intimidated to try? Here's the truth: anyone can do it! With some basic tools, a few IKEA drawers, extra wood, and a lot of determination, you'll have the perfect walk-in closet in your basement. In this detailed, step-by-step guide, we’ll show you how we transformed our basement into a functional and stylish walk-in closet.

Design-phase

Before jumping into construction, we spent time planning out the design. If you’re interested in seeing all the ideas we considered, check out our article: DIY Small Walk-In Closet Designs.

Step 1: Empty out the basement

The first step in building a walk-in closet in the basement is to clear the space. Remove everything that isn’t necessary to create a clean slate for the project. We took down the table mounted on the wall and moved other items out to make room for the construction process. Starting with an empty basement is key to visualizing your layout and ensuring you have enough space to work.

Materials Needed: Basic tools for disassembly

Tools: Screwdriver, Hammer

Step 2: Be smart - use the hight to create more floor-space

In a small basement, utilizing vertical space is crucial. We decided to stack the tumble dryer and washing machine to create more floor space. To do this, we had to lower the stand they were originally placed on. Using a Multi-Cutter Tool, we carefully cut down the wooden sides of the stand and put the top back on, allowing the two machines to stack perfectly.

By stacking the appliances, we freed up a significant amount of floor space, giving us more room to work with while building a walk-in closet in the basement.

Materials: Multi-Cutter Tool

Tools: Saw, Measuring Tape

Now the 2 machines could be stacked, and whola, a lot of space saved.

Step 3: Paint EVERYTHING

With the basement cleared, it’s time to paint. To create a clean, bright foundation, we painted the walls, ceiling, and floor. Before painting, fill any small holes in the walls and ceiling with filler. For the floor, make sure to sand and clean it thoroughly before applying paint. We opted for a white floor paint and applied three layers to ensure a durable and fresh look.

Materials: Wall Filler, White Floor Paint

Tools: Sandpaper, Paint Roller, Brush

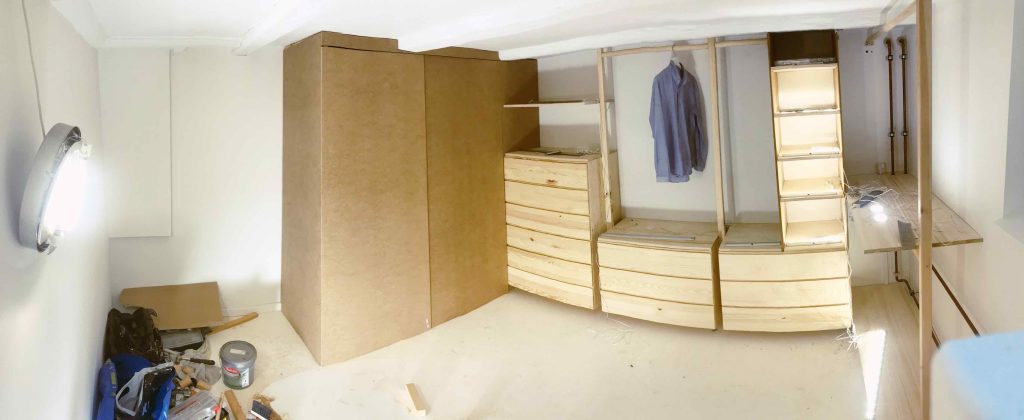

Step 4: Put together drawers

Now that the room is freshly painted, it’s time to start the actual closet build. We used IKEA IVAR drawers, assembling them to determine their exact placement within the room. The positioning of these drawers is essential for creating an organized layout when building a walk-in closet in the basement.

Materials: IKEA IVAR Drawers

Tools: Screwdriver, Measuring Tape

Step 5: Positioning everything and start building first shelf

With the IKEA drawers in place, we started building the first shelf. We ensured there was enough distance between the drawers and the wall for proper support. First, we attached a pole to one of the ceiling beams and extended it to the floor to create the “floating” effect for the bottom shelf. The shelf rests on floor panels around the edges, with the pole providing additional support to prevent tipping.

The pole was secured to the floor using an iron angle and small screws, which we later painted to maintain the seamless floating look.

Materials: Wooden Pole, Iron Angle, Screws

Tools: Screwdriver, Paintbrush

Step 6: Build the second floating shelf

To organize the closet further, we added a second shelf. For this, we attached narrow wooden strips to the wall to create support and added an iron angle for reinforcement. This method helped us achieve the floating appearance again, creating a stylish and functional storage solution as we continued building the walk-in closet in the basement.

Materials: Narrow Wooden Strips, Iron Angles

Tools: Screwdriver, Level

Step 7: Poles for hangers

We installed wooden rods underneath the ceiling and highest shelf to create spaces for hanging clothes. By having these hanger poles at different heights, we created separate areas for shirts and pants, optimizing every inch of space.

Materials: Wooden Rods

Tools: Drill, Screws

Step 8: Add small wall

To add extra support for the top shelf, we built a small wall that rests on the floor. This wall also provides backing for the next set of IKEA drawers, enhancing the “floating” effect. Iron angles were used to secure the drawers to the wall. We temporarily used small wooden pieces to hold up the drawers until all support poles were in place.

Materials: Wooden Panels, Iron Angles

Tools: Saw, Screwdriver

Step 9: Support pole

Another support pole was added to the left side of the IVAR drawer. This pole was attached to the ceiling beam using iron angles and secured to the floor, reinforcing the structure and ensuring stability for the shelving units.

Materials: Support Pole, Iron Angles

Tools: Drill, Level

Step 10: Repeat process

We repeated the same process for the remaining drawers, aligning all three units to create a consistent and streamlined design. This step can be time-consuming, but it’s crucial for achieving a cohesive layout when building a walk-in closet in the basement.

Step 11: Drawers on top of each other

For the left drawer unit, we wanted to stack two drawers on top of each other. To support the additional weight, we built a small wall on the left side, which rests on the floor to provide necessary support for both drawers.

Materials: Wooden Panels

Tools: Screwdriver, Saw

Step 12: Add middle wall on top of IVAR Drawer

We installed another wall in the middle of the first IVAR drawer, using iron angles for added stability. This extra wall creates a divider, making it easier to organize clothes and accessories.

Materials: Wooden Panels, Iron Angles

Tools: Drill, Screwdriver

Step 13: Add small shelves

Several small shelves were added between the two walls, secured with screws from the outside. These shelves make great use of vertical space, perfect for storing shoes, bags, or folded clothes.

Materials: Wooden Shelves

Tools: Drill, Screws

Step 14: Hide washing machine

To keep the closet looking tidy, we built a wall to hide the washing machine. Support for this wall was created using wooden sticks attached to the existing walls and ceiling. Later, we added doors to complete the enclosure.

Materials: Wooden Panels, Hinges

Tools: Saw, Screwdriver

Step 15: Cover up with MDF Plates

We covered the structure with MDF plates, attaching the front ones with hinges to create doors. This gave the closet a clean, polished look, hiding any clutter and keeping the design sleek.

Materials: MDF Plates, Hinges

Tools: Drill, Screwdriver

Step 16: Create shelves in the corner for optimal space usage

In the corner, we installed triangular shelves to maximize every inch of storage space in the closet. These corner shelves are ideal for storing smaller items that might otherwise be lost in larger compartments.

Materials: Wooden Panels

Tools: Saw, Drill

Step 17: Raw build done - now time to spartle

With the raw build complete, it was time to spackle and sandpaper everything down. A smooth surface is key for achieving a professional finish in your walk-in closet build.

Step 18: Get ready to paint

Add a base layer to all areas to be painted and tape off areas you want to protect. Proper preparation ensures a smoother painting process and a flawless final look.

Remember, preparation makes the painting process way easier!

Step 19: Paint everything twice!

Apply two coats of paint to all surfaces for a durable and clean finish. Once the paint dried, we added wooden pieces on top of the drawers to match the shelves’ wood tones.

Materials: Paint, Wooden Pieces

Tools: Paint Roller, Brush

After everything was dry we added pieces of wood on top of the different drawers to match the wood we used to created the shelves.

Step 20: Add Ikea closet lights.

Finally, we installed IKEA closet lights to each area, adding a modern and stylish vibe to the space. The lights make it easier to see and organize everything inside your new walk-in closet.

Materials: IKEA Closet Lights

Tools: Drill

And there we go, all done!

By following this step-by-step guide, we successfully tackled building a walk-in closet in the basement. It was a big project, but the final result was worth every minute. Now, the basement is transformed into a fully functional and stylish storage space that maximizes every inch. Ready to start your own basement closet build? With this guide, you’ll have everything you need to create your dream walk-in closet!

Final result

Cupboard Design For Small Bedroom

Cupboard design for small bedroom

When it comes to creating storage solutions in a small bedroom, making the most of every inch of space is crucial. A well-thought-out cupboard design for a small bedroom can help you maximize storage while keeping the room feeling open and tidy. In this guide, we’ll walk you through our step-by-step process of building the perfect cupboard setup for our own small bedroom. By following this guide, you can create a custom cupboard solution that suits your needs and fits seamlessly into your space.

Step 1: Buy Top Cabinet from Jysk

To start our cupboard design for a small bedroom, we opted for a top cabinet from Jysk. While this cabinet is originally designed for kitchens, its dimensions perfectly fit our bedroom’s layout, proving that thinking outside the box can lead to creative storage solutions. When choosing a cupboard for a small bedroom, it’s all about finding a piece that makes efficient use of vertical space without overwhelming the room.

Materials: Jysk Top Cabinet

Tools Needed: Assembly tools provided by Jysk

Step 2: Put cupboards together, and attached iron angles

We began by following the manufacturer’s instructions to assemble the cupboards. For added support, we used 3D glue during the assembly process to ensure the cupboard would hold up well over time. Before you begin, it’s a good idea to gather all the necessary tools. If you’re building your own cupboard design for a small bedroom, check out our guide: 11 Most Essential Handyman Tools to make sure you’re prepared.

Once assembled, we attached six iron angles to the cupboards. These angles would be used to mount the cupboard securely onto the wall. We used small but sturdy 12mm screws to attach the iron angles, providing the cupboard with strong support when hung.

Materials: Iron Angles, 3D Glue, 12mm Screws

Tools: Screwdriver, Measuring Tape

Step 3: Measure and drill

Accurate measuring is key to a successful cupboard design for a small bedroom. We took our assembled cupboard, with the iron angles already attached, and placed it in its exact intended position on the wall. Using a pencil, we marked the spots for the iron angles’ holes directly onto the wall.

After marking, we drilled holes into the wall where the marks were made. Then, we inserted wall plugs into each hole to ensure the cupboard would have a strong anchor. This step requires precision, so take your time to get the measurements and markings just right.

Materials: Wall Plugs

Tools: Drill, Pencil, Measuring Tape

Step 4: Screws in!

Next, we attached the cupboard to the wall using the iron angles. This step can be a bit tricky, so we recommend having an extra pair of hands to help hold the cupboard in place while you screw it into the wall. This part of the process really makes your cupboard design for a small bedroom come to life, as you see the cupboard securely mounted and ready to be used.

Tools: Screwdriver, Level

Step 5: Repeat

If you’re installing multiple cupboards, repeat Steps 1-4 for each unit. This can be the most time-consuming part of the process, but the end result is worth it. Make sure each cupboard is level and securely fastened to the wall. Taking your time during this phase will ensure a seamless, built-in look for your cupboard design for a small bedroom.

Materials: Additional Jysk Cupboards, Iron Angles, Screws

Tools: Screwdriver, Level

Step 6: Add filler and sandpaper!

To give the cupboards a clean, polished look, we used filler to cover any small cracks or gaps around the cupboards. Once the filler dried, we sanded it down to create a smooth surface. This step makes a huge difference in the final appearance of your cupboard design for a small bedroom, ensuring it looks professionally installed.

Materials: Filler

Tools: Sandpaper

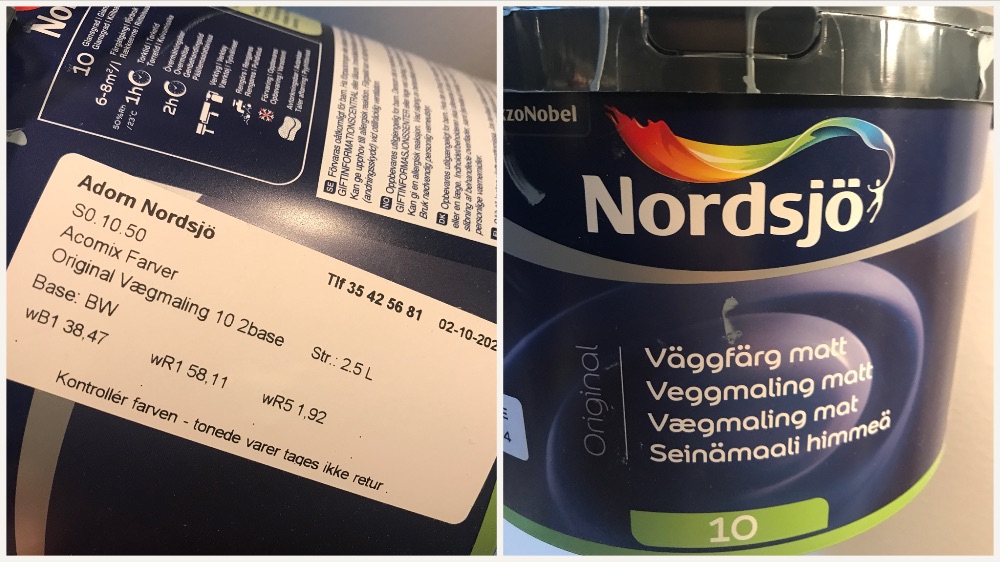

Step 7: Paint the Cupboards

Now, it’s painting time! Before applying paint, we lightly sanded all surfaces for better paint adhesion. We then painted the cupboards twice, using the same paint as our bedroom walls to create a cohesive, built-in appearance. This can be a smart trick for any cupboard design for a small bedroom, as it helps the cupboards blend into the room seamlessly.

Materials: Nordsjö Paint

Tools: Paintbrush, Sandpaper

We used Nordsjö brand paint, and the color code is shown in the picture below. While you can use any color that suits your room, matching the wall paint can help make the cupboards look like an integrated part of the room rather than separate pieces of furniture.

Step 8: Attach doors

After the paint dried, we attached the cupboard doors, giving our storage units a clean, finished look. And that’s it—our cupboard design for a small bedroom was complete! The final result is a functional and stylish storage solution that maximizes space in our small bedroom without compromising on style.

Materials: Cupboard Doors

Tools: Screwdriver

And there we go!

Our take on a cupboard design for a small bedroom is now finished! By carefully measuring, assembling, and painting, we transformed simple kitchen cabinets into custom bedroom storage. This project not only adds ample storage to our small bedroom but also helps keep the space looking neat and uncluttered. With a total investment of around $800 and approximately 30 hours of work, we now have cupboards that fit perfectly into our small bedroom.

If you’re planning to create your own cupboard design, remember that the key is to find cabinets that suit your room’s dimensions and use clever tricks like matching paint and concealed hardware to achieve a seamless look. Now, it’s your turn to bring this design into your bedroom!

Final Thoughts on Cupboard Design for Small Bedroom

When working with limited space, a thoughtfully executed cupboard design for a small bedroom can make a world of difference. By following this guide, you can create storage that fits your space perfectly and adds a custom feel to your room. With the right materials and a bit of patience, you’ll have a beautiful and functional cupboard that makes the most out of every corner of your small bedroom. Happy building!

DIY Floating Kitchen Shelves

DIY Floating Kitchen Shelves

Extra shelf space in the kitchen is always a game-changer, and building your own DIY floating kitchen shelves is a quick and affordable way to add both function and style to your space. In this simple step-by-step guide, I'll walk you through how to create your very own floating shelves with minimal tools and materials. Let’s get started on making these elegant and practical kitchen additions!

Step 1: Cut of the shelf

The first step in making your DIY floating kitchen shelves is cutting the shelf itself. We used a leftover piece of MDF plate for this project. MDF is ideal because it’s sturdy, smooth, and easy to work with. Begin by measuring the dimensions of the area where you want the shelf to hang. Once you have the measurements, mark them on the MDF plate.

Using a simple hand saw, we cut the MDF to the appropriate size to fit perfectly into the corner of our kitchen. If you prefer a more precise edge, you can also use a circular saw, but a hand saw works just fine for this project. The beauty of DIY floating kitchen shelves is that you can customize the size to fit your exact needs!

Materials: MDF Plate

Tools: Hand Saw (or Circular Saw)

Step 2: Attach angle irons

To create the “floating” effect for your DIY floating kitchen shelves, you’ll need to use angle irons. We chose small angle irons to keep them as hidden as possible. The more concealed the supports are, the more convincing the floating illusion will be!

First, attach three small angle irons to the wall in the spots where you plan to place the shelf. Make sure to use a level to get them perfectly straight. We secured the angle irons with wall plugs and screws, ensuring they would hold the weight of the shelf and any items placed on it. The smaller the angle irons, the more they’ll disappear behind the shelf, enhancing the sleek, floating appearance.

Materials: Small Angle Irons, Wall Plugs, Screws

Tools: Screwdriver, Level

Step 3: Rounding of corner

For safety and aesthetics, we decided to round off the outer corner of the shelf. This is especially useful for DIY floating kitchen shelves that will be installed at eye level or in high-traffic areas. If someone bumps into the shelf, a rounded edge is much friendlier than a sharp corner!

Using a multi-cutter tool, we carefully cut away the corner to create a smooth, rounded edge. Then, we used sandpaper to smooth out the surface for a clean finish. If you don’t have a multi-cutter, a hand saw or jigsaw can do the trick—just remember to sand it down afterward for a nice, polished look.

Materials: Sandpaper

Tools: Multi-Cutter (or Hand Saw/Jigsaw)

Step 4: Paint the Shelf and Angle Irons

Painting is a crucial step in achieving that “floating” effect for your DIY floating kitchen shelves. We chose a sleek gray paint for the shelf itself to match our kitchen decor. Before attaching the shelf to the wall, we also painted the angle irons white. This way, they blend seamlessly into the white wall, making them almost invisible and emphasizing the floating effect.

Choose a paint color that complements your kitchen. Whether you prefer a bold color for a pop of style or a neutral tone to blend in, make sure to apply a couple of coats for a smooth, even finish. Allow the paint to dry completely before proceeding to the next step.

Materials: Paint (Shelf and Angle Irons)

Tools: Paintbrush

Step 5: Attach the Shelf to the Angle Irons

Finally, it’s time to attach the shelf to the wall. Carefully place the shelf on the angle irons and secure it with small 13mm screws. These screws are short enough to prevent them from poking through the top surface of the shelf, keeping it clean and smooth.

Once everything is screwed in, step back and admire your work! These DIY floating kitchen shelves come together quickly and add a stylish, practical storage solution to any kitchen.

Materials: 13mm Screws

Tools: Screwdriver

With just a few materials and a little bit of time, you’ve created your very own DIY floating kitchen shelves! This project is a fast, cost-effective way to add extra storage and a modern touch to your kitchen. The floating design keeps the look light and airy, perfect for smaller kitchens where space is precious.

These shelves are not only functional for storing spices, dishes, or decor but are also customizable. You can experiment with different shelf sizes, colors, and finishes to match your kitchen’s style perfectly. So, why not give it a try? Your kitchen will thank you for the extra storage and the sleek, stylish upgrade.

Final Thoughts on DIY Floating Kitchen Shelves

Building DIY floating kitchen shelves is an easy, rewarding project that transforms your kitchen space. By customizing the size, shape, and color, you can create a storage solution that fits your unique style and needs. Plus, the floating design adds a touch of modern elegance without overwhelming the room.

Give this DIY project a go, and you’ll soon have beautiful, functional shelves that not only save space but also add character to your kitchen. Happy building!

Recent Posts

GET IN TOUCH

Copyright @ 2024 - Redesign DIY